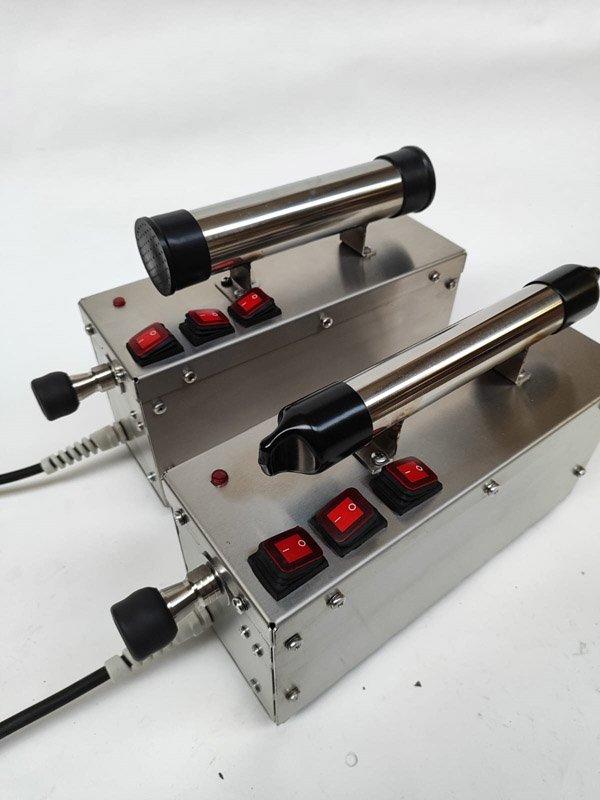

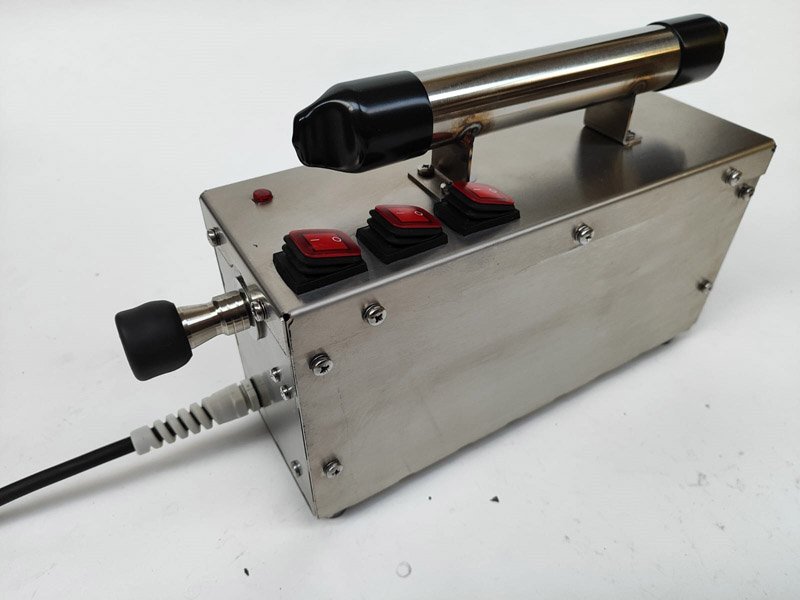

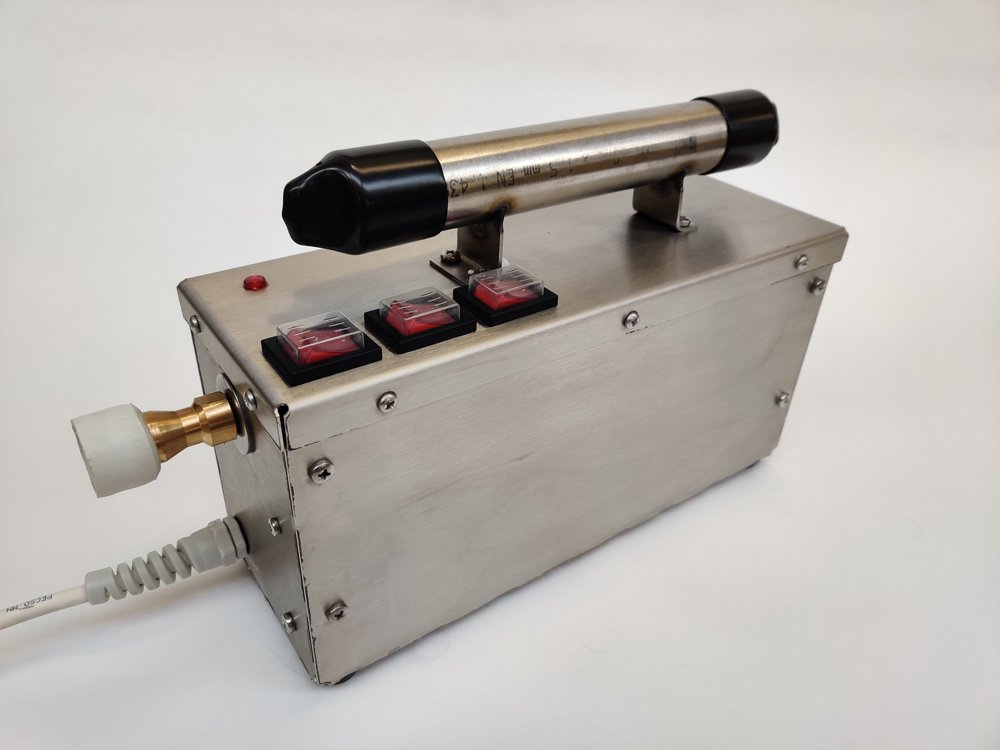

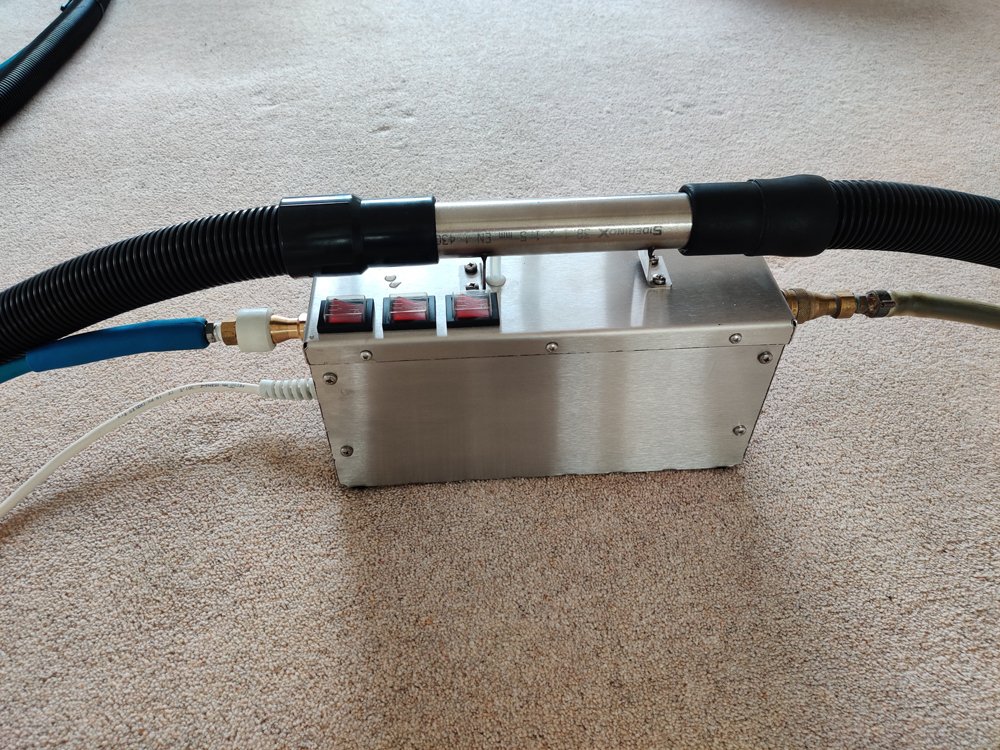

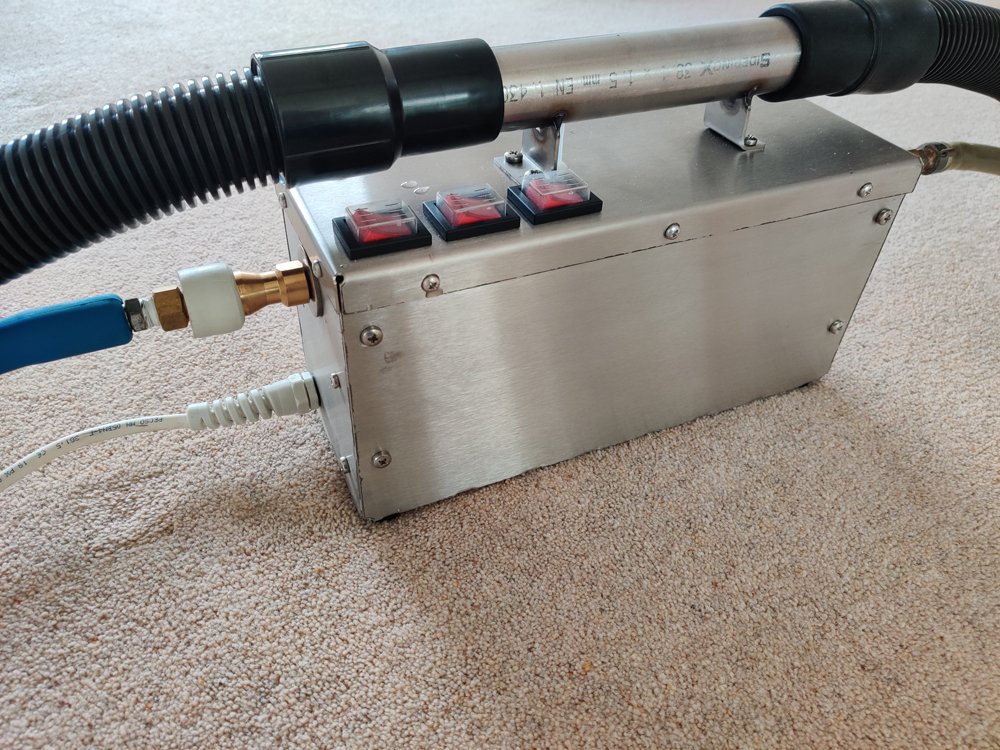

CONSTRUCTION

All stainless steel casing, it’s ultra compact, easy to carry and store. Heavy duty rubber mains cable is tough and easy to wind. Heat shield fitted to outlet coupling. Unique large grab handle also acts as steam reservoir and vac hose joiner.

THERMOSTATS

The Heatbomb is a high-power device using 3 element cores. Each core can be operated independently.

The 3 thermostats used have been specially selected to have a fast response to thermal change. They have a low differential [the number of degrees between switching off and on again].

This is essential to maximise efficiency. Some heaters on the market use 1 variable capillary type stat that are much slower to react and drag down the efficiency of the unit due longer ‘off’ time and bigger differential.

Both types of stats are 16a rated but the 3 in the Heatbomb share the high current load between them and therefore have a much greater life expectancy than the single stat designs having to take the full current load.

HEAT COIL

The Heatbomb has a 316 grade stainless thermal transfer coil installed to be totally resistant to any chemicals. The connection fittings are fully welded to the coil ends giving a leak free life.

Most other makes have copper tube with ends held on by compression fittings that are far more likely to leak after time.

PIPES

All the pipes in the heatbomb are high pressure and temperature resistant. Stainless steel fittings are used on these pipes that will never corrode. Most other heaters use steel hydraulic fittings that rust internally. Stainless fittings are 4 times more expensive than the non stainless type but we think worth it.

BACKPRESSURE VALVE

The Heatbomb is fitted with a special backpressure preventer valve to stop pressure going back down the line to the machine pump and causing damage. The high temperatures reached in the Heatbomb can act like a steam boiler and increase pressure to beyond what is safe for many pumps and internal machine hoses. This special valve is essential to eliminate any worries to equipment.

STEAM VENT VALVE WITH RESERVOIR

When temperatures go above 100deg water wants to expand and turn to steam.

The Heatbomb reaches 120deg and therefore needs a steam vent valve to vent any expanding steam out. The steam is collected in a special reservoir to condense back to water. Having this valve means that the heatbomb can safely get hotter than heaters without a vent valve.

‘If it hasn’t got one then maybe it doesn’t need one because it does not get hot enough.’

THERMAL TRANSFER BLOCK

This is a large aluminium block that stores the heat from the elements. It’s BIG, probably the biggest on the market which helps the efficiency to be the best.

The block is made from a specially selected grade of aluminium that has the highest thermal conductivity possible.